Article • 12 min read

Sales and operations planning (S&OP): Definition, process, and best practices

See how sales and operations planning uses data to zero in on supply and demand issues so you can balance your business processes and set your teams up for success.

著者: Donny Kelwig, Contributing Writer

更新日: June 7, 2024

Most businesses put themselves in a customer’s shoes when creating their sales strategy. They ask themselves questions like:

What do customers want?

How do we make customers happy?

What are the best upsell strategies?

While centering your business around the customer is important, no company can provide high-quality customer experiences if it can’t communicate effectively, suffers from poor collaboration across departments, or has other internal issues in serious need of repair.

That’s where sales and operations planning (S&OP) comes in. It’s one of the most important tools you can use for developing and maintaining internal business health. Follow along as we take you through the S&OP meaning, process, and purpose.

What is sales and operations planning (S&OP)?

Sales and operations planning is the process by which leadership and executive teams collaborate to ensure all departments are balanced and functioning properly.

Ideally, the sales and operational planning process align the company’s financial plan with the supply and demand of the current products. S&OP finds solutions that reduce the inefficiencies that can arise from wasted resources, poor customer service, or over/underproduction.

A lack of collaboration and communication is a major cause of workplace failure, but it’s more common than you might think. In the Zendesk Customer Experience Trends Report 2022, 26 percent of organizations surveyed admitted that they need to identify new ways to enable cross-department collaboration.

It’s safe to say that your S&OP process is likely in need of a refresh, too—doing so can take your business to the next level. Recent studies show that companies with successful alignment are a whopping 67 percent more effective at closing deals.

These numbers should be a wake-up call for anyone who doubts the power of business communication and sales operation planning. Let’s dive into the S&OP process and purpose to make sure your company is one of the few rising to the top.

Sales and operations planning purpose

Organizations have a lot of moving parts. The purpose of S&OP is to create alignment throughout the business. Companies may leverage S&OP to:

Improve the entire customer experience

Balance supply and demand

Increase transparency across departments

Improve communication between teams

Enhance inventory management

Refine processes

Improve budgets and sales forecasts

Expand organizational knowledge of a product’s lifecycle

Sales and op planning might occur monthly, yearly, or any other time increment that makes sense. It all depends on the company and its objectives.

Sales and operations planning benefits

S&OP drastically improves communication and consistency across departments, but there are numerous other benefits as well. The pros of S&OP go far beyond simply getting everyone on the same page.

With S&OP, companies can:

Gain more accurate data—enabling faster, more frequent adjustments in the supply chain and sales pipeline to fix problems in real time.

Optimize resources, reduce waste, and boost productivity.

Eliminate departmental silos to align data points and increase efficiency.

Improve customer service with better inventory and backlog management.

- Fight stagnation by finding easy adjustments to internal and external barriers and updating the sales process accordingly.

Use unbiased data to create achievable KPIs across teams.

All these benefits come from the unification of departments and data. When everyone works from the same numbers, each team can better serve the others. When you have strong S&OP, by the time you get to the customer and the sales journey, you’re already ahead of the game.

Which stakeholders are in the S&OP meeting?

To better understand the S&OP process, you need to know who’s on your team. Here’s a breakdown of the average S&OP meeting room:

Executive management: This is your CEO or C-suite executive. They run the meeting and hold the company accountable for following the approved plan. Additionally, executive management serves as conflict resolution and makes final decisions if necessary.

Department leaders: These leaders represent every department in a company. There should be a representative (usually a manager) present from each team. These leaders speak to their department’s performance and ensure their employees stick to the plan.

Demand planner: The demand planner analyzes statistics on past and present demand to create accurate demand forecasting before the meeting. They then present all demand-related information.

Supply planner: The supply planner presents similar information to the demand planner, but they also review the supply chain, inventory, and orders regularly to reduce over/underproduction.

Operations leader: The operations leader works with supply and production to make sure all operations are functioning at a level that will meet the S&OP plan. They also present actual vs. forecasted performance data regarding inventory and address any backlog.

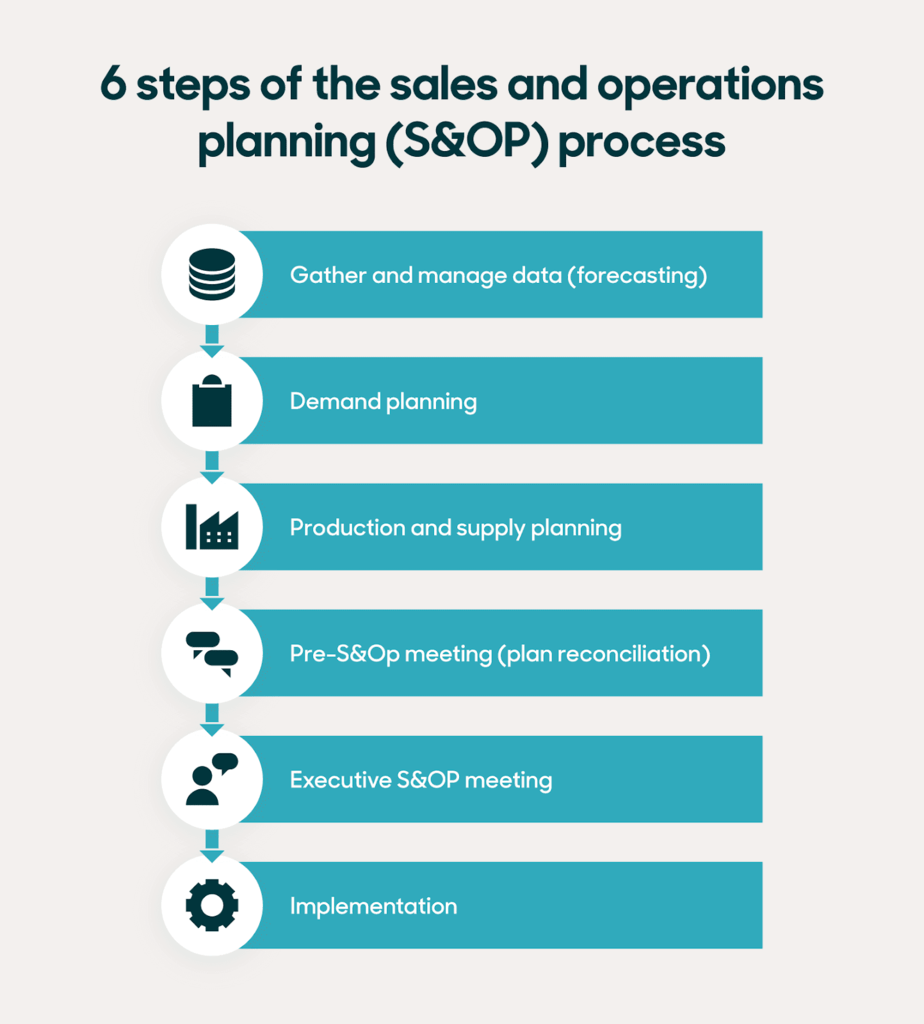

6 steps of the S&OP process

The S&OP process is more than just a meeting. The process starts with gathering data and ends when the plan is fully implemented. But you’re likely wondering: How can sales and operations planning be integrated? Here are the six steps of the S&OP process.

1. Gather and manage data (forecasting)

Each team collects data for the given time period, including:

Past sales

Trend analysis

Plan success rates

Accuracy

This data is formatted into forecasts for the demand planner. The key departments involved are sales, marketing, operations/supply, logistics, and finance. Ideally, your company has software that compiles this information on an ongoing basis, but if not, you may want to consider investing in a CRM.

2. Demand planning

After accounting validates the forecasts for variability, they will make adjustments and build a demand plan. The plan includes:

Customer service policies

Promotions

One-time events

New launches

This step is managed by the demand planner, but sales and marketing should provide input on the finalized plan before the S&OP meeting.

3. Production and supply planning

Using the demand plan, the head of supply works with operations to create a supply plan. This includes:

Inventory targets

Safety stock

Production methods

Possible liabilities in capacity

Inventory

Scheduling

Any necessary pre-launch logistical changes should also be included in the presentation.

4. Pre-S&Op meeting (plan reconciliation)

The supply and demand plans are reconciled, and changes are made based on how realistically the plans accommodate each other. Finance is an essential department in this step, as all plans must be kept within a pre-established budget. If a significantly costly obstacle comes to light, this is the time to assess if the company has the funds to move forward with this plan or if certain aspects need to wait for the next fiscal year.

5. Executive S&OP meeting

Once everything is finalized, the plans are presented at the executive S&OP meeting. By the end of the meeting, there should be an implementable, agreed-upon plan for the entire company.

6. Implementation

Each department leader works with their team as well as cross-functionally to make the changes required in the plan. Regular evaluation of the implementation is recommended.

Free sales and operations planning tools

Ready to mind your business? Take your company to the next level with our free sales and operations planning template.

S&OP best practices: Tips for collaboration between sales and operations

Now that you’ve learned the meaning of S&OP and how to organize an S&OP meeting, how do you make the most of it? Here are a few best practices for creating alignment and facilitating collaboration between sales and operations.

S&OP metrics

Going through the S&OP process can be difficult, even in the most organized of companies. We recommend tracking the following metrics and KPIs to end your S&OP session with comprehensive data:

- Total sales: the total sales in your given time period (month, year, quarter, etc.).

- Sales forecast vs. actual total sales: your total sales in comparison to the expected amount of sales for the given time period.

- Gross margin: the net sales once you subtract the cost of goods sold and services provided in the given time period.

- Working capital: the difference between your current assets and current liabilities in a given time period.

- Inventory turnover: the number of times your inventory is sold and replaced in a given time period.

- Capacity utilization: the percentage of an organization’s potential output that is actually being realized.

- Cycle times: the time spent producing an item or providing a service from the start of the first task through the end of the last task.

- Production forecast: the projection of how many end items will be needed to meet the sales forecast.

How a CRM simplifies your S&OP

S&OP is all about using accurate data to shape the future of your company—and nothing tracks accurate data like a strong CRM. With Zendesk Sell, our sales CRM, data gathering is an automated breeze. Not only can you monitor numerous KPIs with guaranteed accuracy, but you can also make this data available to every team member. When all employees are on the same page and working from the same set of data, your customers and your profits reap the rewards.

Zendesk Sell can help your business hit the ground running quickly with features that include:

Easy integration

Automation

Customization

Reporting

Request a demo of Zendesk Sell today and witness the benefits of fast and accurate data for your sales and operations process.